Since its discovery in 2004, graphene has been hailed as a wonder material, leading to over 25,000 patents for its potential applications. In the decade since, few have reached consumer applications because the cost to produce graphene has been prohibitively high. The good news: production costs and methods are changing for the better, thanks to recent innovations by researchers at the University of Glasgow. This could mean better bulletproof armor, light bulbs, artificial limbs, and even bionic spiderwebs becoming a reality in the near future.

University of Glasgow researchers have discovered a way to cut the cost of large scale graphene production by 100x, thanks to utilizing cheap copper foil that typically powers lithium-ion batteries. The research team took the established graphene production method of chemical vapour deposition—in which gaseous reactants form a film on another surface—but wanted to mimic it with a more cost effective component than the expensive copper typically used. The team were the first to try ultra-thin copper foil for the graphene formation, and the smooth surface of the foil worked even better than anticipated.

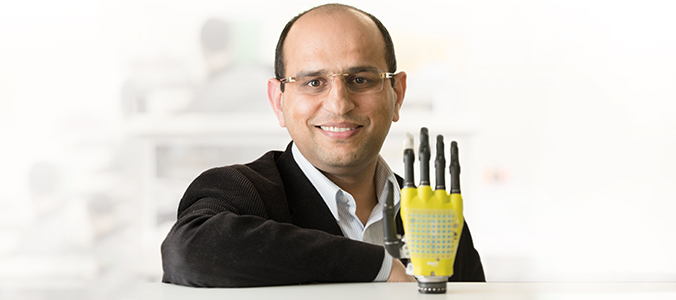

In addition to hitting upon a production method 100x cheaper, the research team found that this production method also led to better performing optical and electrical transistors than previous production methods. Led by Dr Ravinder Dahiya, the research findings, published in Scientific Reports, are significant because they take us one step closer to graphene being a huge game changer in health care, mobile tech, and beyond. We’ve already talked about 10 ways graphene will change the world; now that production costs are coming down, we will likely see many of these innovations hit the market in the next few years.

Dr. Dahiya’s field of study has been focused on synthetic skin. Graphene, he believes, will change the way prosthetic limbs are manufactured. More importantly, graphene might be able to provide sensation for users in ways that today’s cutting edge prosthetics simply cannot. How? Graphene is very flexible and conducive, which could be a game changer for today’s prosthetics, which are typically made of carbon fiber composites.

Every week scientists are finding exciting new applications for graphene to innovate the status quo. With the production breakthroughs brought on by Dr. Dahiya’s research, we’re one step closer to living in a world made smarter through amazing nanomaterials. For the full report on this lower cost production method for graphene, check out the Scientific Report abstract.

Photo: University of Glasgow