How Graphene Can Be Used in Military Protective Gear

Graphene is a two-dimensional material with remarkable physical and chemical properties, including high strength, high conductivity, and high flexibility. These properties make graphene an ideal candidate for a variety of applications, including military protective gear. Here are some of the potential applications of graphene in military protective gear and the benefits it could provide to soldiers.

One of the main applications of graphene in military protective gear is in body armor. Graphene is one of the strongest materials known to man, with a tensile strength 200 times greater than steel. This makes graphene an ideal material for body armor, which is designed to protect soldiers from bullets and shrapnel. Scientists in Spain recently combined graphene with silk to create a nano-composite material capable of withstanding military ammunition that is also more comfortable to wear than existing body armor, which is another significant benefit. Because graphene-based body armor would be significantly lighter than traditional body armor, soldiers could move around more easily and maneuver in combat situations while still being adequately protected.

In addition to body armor, graphene can also be used in helmets to protect soldiers from head injuries. Graphene has been shown to be an excellent shock absorber, which could help reduce the impact of a blast or other traumatic event. This reduces the risk of traumatic brain injuries and other head injuries, which are extremely common in combat situations. It can also be used in other types of protective gear, like gloves and boots. Graphene-based gloves would provide increased grip and durability while still giving soldiers the dexterity they need to operate weapons and other equipment, and graphene-based boots would provide increased protection against explosive devices.

Graphene would also make an excellent material for sensors due to its high sensitivity and low noise characteristics. Graphene-based sensors could be used to detect chemical, biological, and explosive threats, providing soldiers with advanced warning and increased situational awareness. Drones and vehicles would also benefit from this type of material as well, as graphene-based composites would make them lighter, stronger, and more efficient.

While there are many potential applications of graphene in military protective gear, there are some challenges as well. Graphene is still a relatively expensive material to produce. Additionally, new production methods will need to be developed in order to produce large quantities of graphene for military applications. Then, there’s also the uncertainty surrounding the long-term health effects of graphene. While graphene has been shown to be biocompatible, there is still some concern about the potential for graphene to accumulate in the body over time. More research is needed to fully understand the potential health effects of graphene.

Despite these challenges, the potential benefits of graphene in military protective gear are significant. As research into graphene continues, we will continue to see even more applications of this remarkable material in the military and beyond.

The Implications of Graphene Electrodes’ Ability to Split Water Molecules

Whether the discussion centers on e bikes, airplanes or nearly any mode of transport in between, there is an increasing focus on hydrogen-powered propulsion systems. Such systems are far more environmentally friendly, in no small part because their only emissions are water droplets, as opposed to the harmful greenhouse gasses typical of internal combustion engines.

As a result, we have seen major automobile manufacturers like Toyota, BMW, Honda and Hyundai explore hydrogen fuel-cell technology. We have seen the announcement by Airbus in December 2022 that it plans to stage test-flights of a hydrogen-powered jet by 2026, and debut such an aircraft within a decade of that. And yes, we have heard talk of ebikes powered by hydrogen cells as well.

There are questions about infrastructure: Were you to drive a hydrogen-powered vehicle, where would you stop to fuel it? There are only 80 such stations in the entire U.S., according to BMW. So even if you wanted to adopt this particular green technology, you simply couldn’t use it, if you hoped to travel any great distance.

But here’s an even bigger concern: Most hydrogen is at present produced from coal or natural gas. Seems like there ought to be a better alternative.

Thanks to graphene, there might be. The website Graphene-info.com reported in October 2022 that researchers used graphene as an electrode while breaking water molecules. That made it possible for them to apply a stronger electrical current while performing this process, known as dissociation. Previously, using a stronger current had not hastened dissociation, but graphene – a layer of carbon that is just one atom thick – was permeable only to protons, fostering a separation from the hydroxide ion in the water molecules and preventing a recombination. As noted in the Graphene-info piece:

This charge separation is essential to observe the electric field acceleration of water dissociation. Another key advantage of graphene is that it allows evaluating the electric field at the graphene-water interface experimentally, which allows for quantitative characterization of the field effect.

The hope, again according to the piece, is that this will hasten the development of hydrogen fuel from water – “that it can help design better catalysts for green hydrogen production,” as Dr. Marceo Lozada-Hidalgo, leader of an international team of scientists that performed the study, told the site.

Again, the implications are vast. The first hydrogen-powered vehicle was developed in 1966, but according to the website Thedrive.com, it wasn’t until 50 years later that such a vehicle was produced in a volume exceeding 1,000. That’s when Toyota came out with a car called the Mirai.

That same website reported that only 8,000 hydrogen-powered cars were sold in the U.S. between 2012 and 2020, in large part because of the aforementioned infrastructure concerns. Those 80 fueling stations? Apparently they’re all in California, according to Thedrive piece, which added that the network isn’t always the most reliable.

Still, green hydrogen projects continue. According to a February 2021 report by the Hydrogen Council, there were 228 projects around the world. Just 19 of them were in North America, however, as compared to 126 in Europe. Many of those projects, the result of government initiatives, had yet to be adequately funded at that point.

The Hydrogen Council nonetheless estimates that hydrogen production will increase to 6.7 million tons by 2030, a figure that far exceeds the council’s previous estimate of 2.3 million tons. It’s a matter of getting it to the right people with the right vehicles, at the right time. And it appears that graphene can help make that happen.

Graphene’s Potential Role in Developing Space Habitats

It has been 50 years since man last walked on the moon, but it appears that is about to change. Billionaires have been rocketing into orbit for a while now, and public concerns have likewise announced bold intentions.

NASA’s Artemis program, for example, plans to land a woman or person of color on the moon, perhaps as early as 2026 – a departure, seeing as the 12 previous people to walk the lunar landscape (including the last of those, Gene Cernan, in 1972) were all white males. Moreover, Artemis, which works in conjunction with commercial and international partners, announced on its website that it hopes to one day build a base camp on the lunar surface.

The ultimate goal – for Artemis and others – is Mars, with the moon serving as a way station and training ground. But there is much to be gained on the moon itself, not the least of which are crucial materials that can aid in earthly pursuits, like neodymium for electric motors and helium-3, which is essential for nuclear fusion

There are those who wonder if there is in fact a need for human space travel, given the harsh conditions and the fact that at some point robots will be able to handle tasks like mining the above materials. But SpaceX head Elon Musk, who along with fellow billionaires Jeff Bezos (Blue Origin) and Richard Braanson (Virgin Galactic) is at the forefront of the new space age, argued in 2016 that to stay on Earth means risking an “eventual extinction event,” and that the far better option is to become a “spacefaring civilization.”

Far more recently, he said he is “highly confident” that SpaceX will put a man on Mars by 2026. He also predicted that there will be a city of one million people on the Red Planet by 2050. Others believe there will be a colony — not a city, but a colony — on Mars between 2040 and 2050. Making that a reality, however, means finding a way to house people in structures that can withstand the harsh conditions in space. On the moon alone, for example, the temperature can vary between 224.6 degrees during the day and minus-243.4 degrees at night. There are also the matters of radiation and micrometeorites and space junk.

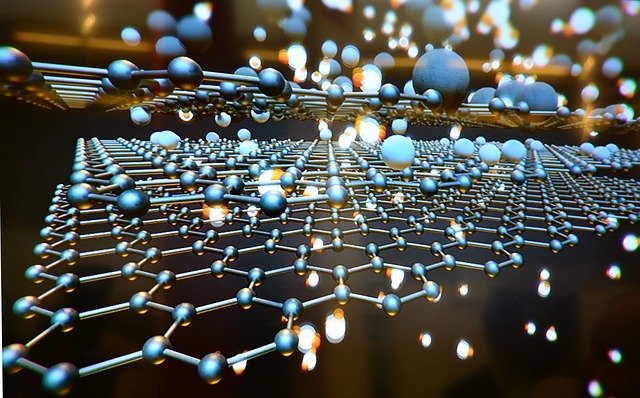

Graphene is one possibility. This one-atom-thick layer of graphite, first isolated in 2004, is 200 times stronger than steel. It can withstand temperature extremes. It is flexible and conductive. Vivek Koncherry and James Baker, professors at the University of Manchester in the UK, have done ground-breaking work in this area, and argued in a recent report that “some of the biggest challenges to space habitats can be solved through the use of graphene and other 2D materials.”

Not without reason, then, did the two researchers say that space represents a “new frontier,” not only for the explorers but the scientists looking to give them the best possible means to succeed. In saying that, they faintly echoed actor William Shatner, who played fictional captain James T. Kirk on the 1960s television show “Star Trek” (and who, at age 90, was a passenger on one of Bezos’ Blue Origins flights in October 2021). Shatner/Kirk always called space “the final frontier.” But you get the idea; everybody in the scientific community is through the glass darkly now, taking on challenges that might have once seemed insurmountable.

Now, not so much. Koncherry, Baker and Co. have even developed the prototype for a graphene-based space habitat, while partnering with the architectural firm Skidmore, Owings & Merrill (SOM), which designed the world’s tallest building, Burj Khalifa, in Dubai. Tim Newns, Chief Executive of MIDAS, Manchester’s inward investment agency, told the university’s website that this development “underlines the breadth of applications where advanced materials and in particular graphene can revolutionize global industries such as the space industry.”

And not a moment too soon, considering where the sector appears to be headed – literally, financially and every other way. The space economy is expected to soar past the $1 trillion mark by 2040, so innovation will no doubt continue. And graphene will be central to that.

How Graphene is Impacting the Art World

We already know that graphene, a one-atom-thick layer of carbon discovered in 2004, can be used as a conductor, insulator and filter – that it can even be used to create ultra-light, ultra-thick body armor, as well as wearable electronics.

What has recently come to light, however, is that graphene can also impact the art world, whether it is fashioned into art itself or used as a means to preserve existing works.

A September 2021 study published in the scientific journal Nature Nanotechnology concluded that graphene, when placed in what has been described as “an invisible veil” over certain paintings, will prevent fading by as much as 70 percent. That’s because graphene blocks ultraviolet rays and is impermeable to oxygen, moisture and other agents that might corrode any given piece of art.

Costas Galiotis, a chemical engineering professor at University of Patras in Greece and a member of the executive board of the European Union’s Graphene Flagship research initiative, was part of the team that performed the study. He called this technique “the perfect solution to protect colors from photodegradation” in an interview with the website ARS Technica and added:

“The innovation of our approach is based on the fact that graphene adheres to any clean surfaces, but it can easily be removed, in contrast to current commercial polymeric coatings. Thus, it exhibits a competitive advantage over other protective materials and substances for the protection of artworks from color fading.”

Narayan Khandekar, director of the Straus Center for Consolation and Technical Studies at the Harvard Art Museums, pointed out to the website Chemistryworld.com that in order to limit fading artworks have traditionally been stored in darkness and then displayed for a limited time under low-energy lights. He called this new development “really compelling” and a method that “has a lot of potential.”

Galiotis and his team settled on the technique after closely examining the discoloration of some of Vincent van Gogh’s works. First tested on the paintings of an artist named Matina Stavropoulou, it involves attaching the graphene veil with the aid of polyester/silicone adhesive. It can easily be removed, the team asserts, without damaging the painting.

The team cautioned that this veil works best on smooth surfaces, and expressed concerns about warping and/or certain corrosive compounds becoming trapped beneath the graphene layer. But overall, this appears to be a breakthrough.

No less interesting was the development by a group of Rice University scientists of artwork through the use of laser-induced graphene in 2019. One of them, Joseph Cohen, told the website Phys.org that the goal in creating his rendering – of a landscape – was to “not make it kitsch or play off the novelty, but to have it have some true functionality that allows greater awareness about the material and opens up the experience.”

One year earlier artist Mary Griffiths collaborated with Nobel laureate Sir Kostya Novoselov on a microscopic graphene-based version of one of her works.

As with most art, the goal is to make a lasting impression. The new graphene-based technique pioneered by Galiotis and Co., meanwhile, is designed to ensure that that will be the case.

The Ferroelectrical Qualities of Graphene, and What They Mean for the Future of Electronics

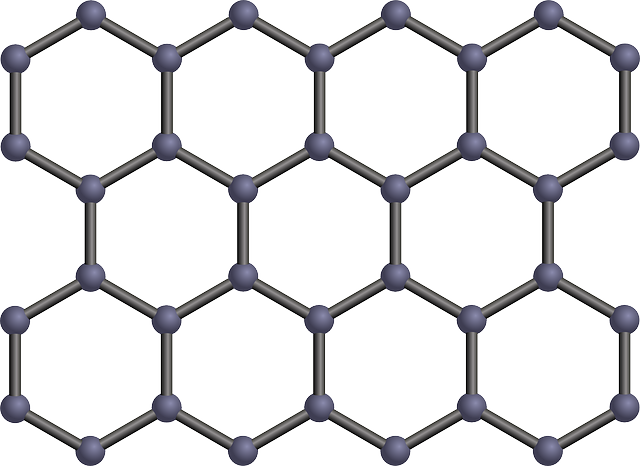

It has long been known that graphene can serve as a superconductor or insulator. But in February 2021, MIT researchers discovered that this material, an atom-thick layer of carbon arranged in a hexagonal pattern, is even more versatile than anyone might have imagined: It also exhibits ferroelectrical qualities. In other words, it spontaneously polarizes.

That discovery “may pave the way for an entire generation of new ferroelectrics materials,” as Pablo Jarillo-Herrero, the MIT physics professor who led the study, put it in a post on the university’s website.

Specifically, the post noted the implications for neuromorphic computing, a type of computing that approximates the workings of the human brain and nervous system. As noted on the site HPE.com, it does so by creating something known as spiking neural networks, “where spikes from individual electronic neurons activate other neurons down a cascading chain.”

And that, the post added, is not unlike the manner in which signals are exchanged between the brain and neurons in various parts of the body.

There is some expectation that this technology will come into vogue in the very near future, as legacy systems grow outdated and a need arises in certain specific technological areas — that it will not necessarily displace traditional computing so much as augment it. Emre Neftci, assistant professor in cognitive sciences at the University of California, Irvine, and head of the university’s Neuromorphic Machine Intelligence Lab, cited for HPE the example of artificial intelligence at the edge. Other use cases will certainly arise, as evidenced by the fact that Emergen Research projects that by 2027, the neuromorphic processing market will balloon to $11.29 billion.

Certainly MIT’s discovery about graphene represents another significant step in that direction. The breakthrough about ferroelectricity, which to date has been notably used in such things as medical ultrasounds and Radio Frequency ID (RFID) cards, was the result of Jarillo-Herrero and his team sandwiching two layers of graphene between layers of boron nitride.

While opposite charges are normally attracted to one another in most materials, that was not the case in this study, which built upon work done by the same team in 2018. In fact, the result was a form of ferroelectricity that differs from that which had previously been seen.

Harvard physics professor Philip Kim, who was not involved in this research, called this development “fascinating” in the piece on the MIT site and added:

“This work is the first demonstration that reports pure electronic ferroelectricity, which exhibits charge polarization without ionic motion in the underlying lattice. This surprising discovery will surely invite further studies that can reveal more exciting emergent phenomena and provide an opportunity to utilize them for ultrafast memory applications.”

In other words, we are just scratching the surface of everything graphene can do, which stands to reason — it was only discovered in 2004. As exciting as this development is, more certainly lies ahead.

Where the Rubber Meets the Road: Converting Tires Into Concrete-Reinforcing Graphene

Concrete and discarded rubber tires represent two of the world’s greatest environmental hazards. Is it possible that a discovery by a team of Rice University scientists earlier this year could help curtail the impact of both?

Using the same “flash” process that the team first introduced in 2020 — i.e., giving old tires a jolt of electricity that left only carbon atoms behind — the researchers were left with turbostratic graphene, once the atoms reassembled. The solubility of this material enabled it to be incorporated into cement to produce concrete that is more environmentally friendly than its current incarnation. (Nearly all U.S. roads are comprised of asphalt concrete, a mixture of rocky aggregates and a petroleum-based binder.)

According to one estimate, the world produces 4.4 billion tons of concrete annually, though other estimates put that number as high as 10 billion. Either way, no other man-made material is used as much, and among earthly substances of all kinds its consumption is exceeded only by that of water.

That comes with a heavy environmental price, as concrete accounts for four to eight percent of global carbon dioxide emissions and soaks up 10 percent of the industrial water that is used, most of it in countries that can ill afford such profligacy. Small wonder that the headline atop a 2019 piece on The Guardian’s website described concrete as “the most destructive material on earth.”

The development by the Rice team could at least begin to address that.

“If we can use less concrete in our roads, buildings and bridges, we can eliminate some of the emissions at the very start,” one team member, chemist James Tour, told Science Daily.

The added benefit that would result from widespread implementation of this technique would be whittling away at the mountain of used tires that are a pox on the world’s landscape. Some 1 billion tires are discarded every year, and only 10 percent are recycled.

According to a post on the Environmental, Health and Safety (EHS) Daily Advisor, the recycling rate in the U.S., where some 300 million tires are discarded annually, is much higher — 76 percent in 2019, down from 96 percent six years earlier. A post on the site Intelligent Living takes issue with those calculations, pointing out that they include tires that are shredded and used as tire-derived fuel (TDF), which creates environmental problems of its own.

What can be agreed upon is that tires constitute a sizable issue, whether the chemicals that comprise them is leaching into the environment or they’re taking up an outsized amount of space in landfills (and even bubbling up to the surface when buried, because of the gasses that they trap). There’s also the potential danger of fires, and the way in which tires trap water, making them a breeding ground for mosquitoes.

Other recycling methods have been developed beyond creating TDF, including the creation of rubber mulch for use on playgrounds and the like, and extracting the steel, nylon and fiber and repurposing it. But the development by the team at Rice represents another promising step forward, one that can potentially combat two environmental menaces at once.

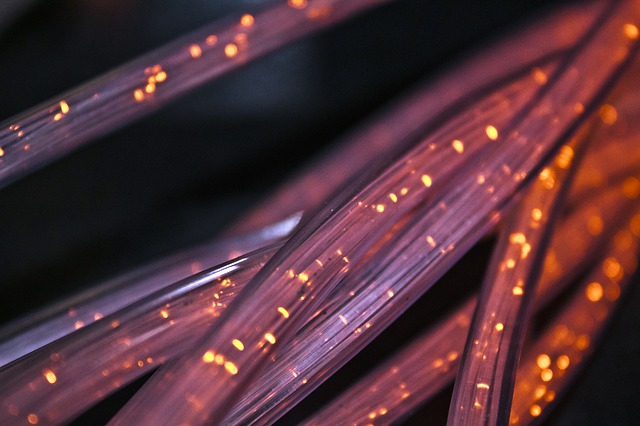

Can Graphene Supercharge the Internet?

Faster — it’s the buzzword of the century. We want it all and we want it faster. Unfortunately, faster is impossible in some cases. We’ll never be able to control how quickly a waitress brings our coffee or how long it takes our children to clean their rooms. We can, however, control the internet and recent research says that yes, we can make it faster — with graphene.

Currently, we transmit data from the internet using fiber optic cables and electro-optic switches. The data is converted to light at one end, travels at the speed of light through a fiber optic cable, and is interpreted and transmitted at the other end. Fiber optic switches control where the data goes by “switching” electronic circuits on and off. At present, these switches can do their job in a few picoseconds. That’s one trillionth of a second which is impressive, but not as fast as graphene.

While there are new developments still to come, graphene’s breakneck speed is expected to have widespread implications when 5G becomes commonplace. As 2D materials scientist Dr. Nicky Savjani said, “The science of graphene is still in its infancy; we are still learning so much about its fundamental properties.” She did add, however, that new insights are coming at “staggering rates.”

Scientists have long suspected that incorporating graphene into fiber optic pathways could significantly speed up the internet. The pure carbon substance frequently referred to as the “miracle material” is extremely strong, amazingly thin, and both thermally and electrically conductive. It wasn’t until 2013, however, that researchers at the Universities of Bath and Exeter found a way to prove just how much graphene could speed up optical response rates.

Normal optic switches work by moving their electrons from low to high energy states and back again through what’s known as an energy gap. The response time we measure — meaning the one that has a direct effect on your internet speed — is the length of time it takes for the electron to return to its low energy state. This timeframe is commonly referred to as recombination time. Because graphene conducts energy but doesn’t possess the standard energy gap, it was difficult to accurately identify a recombination time.

The university researchers chose instead to study graphene’s electron behavior in the infrared spectrum as it transitioned between states. What they found was astonishing. An optical switch that used just a few layers of (stacked) graphene responded in a mere one hundred femtoseconds. That’s almost 100 times faster than the fiber optic switches discussed above. Faster electro-optic switches translate to a faster internet experience.

Subsequent discoveries suggest that graphene computers could be 1,000 times faster, though they remain in the theoretical stage.

Graphene is man-made entirely out of carbon which can be found everywhere. Its abundance means we’re unlikely to run out, so graphene should remain relatively inexpensive despite its increasing popularity across various industries. And, because the material works in conjunction with and not in lieu of fiber optic cables, there’s no need to completely replace current telecommunication systems to achieve upgraded internet response times. Manufacturers would only need to update the switches located at the end of the cables.

Researchers are consistently coming up with new and innovative ways to incorporate graphene into our daily lives. In fact, there were approximately 30,000 graphene-related patent filings between 2004 and 2017. Perhaps a faster internet is only the first in a series of telecommunication upgrades catalyzed by the miracle material.

Are Graphene Composites the Key to Wider Application?

It is a well-established fact that there is far more to graphene than meets the eye. It is just a one-atom-thick layer of graphite, meaning it is one million times thinner than the diameter of a human hair. Yet it is the strongest man-made material ever made — 200 times stronger than steel, in fact. It also conducts electricity 13 times better than copper and conducts heat at enhanced levels as well. And finally, it is lightweight, flexible and corrosion-proof.

That means it has implications in a wide variety of fields, including electronics, robotics and even the medical sector. Beyond that, there is graphene’s potential when used as part of a composite material, usually with resins or polymers (and often in the tiniest of amounts). Given all the factors just mentioned, that has wide-ranging implications as well, particularly for the transportation industry.

Certainly researchers are just scratching the surface with graphene, as it was only discovered in 2004. There are miles to go. There is much to be discovered. But for now, it is interesting to note that one of the first companies to make headway with this material was in fact HEAD, a sporting-goods company known for its tennis rackets.

In 2013 it produced a graphene-based racket that was 30 percent stronger and 20 percent lighter than its predecessors, then developed lightweight, flexible skis using the same substance. Also notable was the development of graphene-based golfballs by Callaway.

Philip Rose, CEO of the Michigan-based graphene nanoplatelets manufacturer XG Sciences, told the website Compositesworld.com that the impact of innovation in the sporting-goods industry, given its high profile, “can become quite broad” across other sectors.

Rose’s company, for instance, partnered with Ford Motor Company to develop components in the F-150 Truck and Mustang that included graphene-laced polyurethane foam. It was found that that resulted in a 17 percent noise reduction, a 20 percent improvement in mechanical properties and a 30 percent improvement in heat endurance.

Fiat and Lamborghini have also used parts involving graphene composites, as has the Briggs Automotive Company, which makes single-seat, street-legal sports cars.

The aviation industry has also delved into graphene composites, notably using them in the construction of planes’ wing and tail sections. The Graphene Flagship, a 10-year, $1 billion research program launched in January 2013 by the European Union, has partnered with Airbus to develop graphene-based de-icing systems for aircraft, and the industry-wide hope is that composites involving that substance can go a long way toward making planes lighter, more fuel-efficient and more environmentally friendly — no small consideration, considering the transportation industry gobbles up 33 percent of the world’s energy and in the U.S. alone contributes 28 percent of the greenhouse gas emissions.

The bottom line is that graphene — amazing as it is on its own — is capable of contributing even more when used in combination with other materials. We are only beginning to see its possibilities, as this is an ongoing process, with other developments undoubtedly just over the horizon.

What Magnetic Graphene Might Mean for the Future

Scientists have figured out a way to magnetize graphene, which could make possible lightning-fast microcomputers and electronics that defy the imagination. But as with graphene itself, the full potential of the magnetized version of this substance — an atom-thick layer of graphite — has yet to be realized.

Certainly, though, this represents another step forward for graphene, which was discovered only in 2002 by Andre Geim, a physics professor at the University of Manchester, in the United Kingdom. Some 12 years later, a New Yorker headline breathlessly raised the possibility that graphene “may be the most remarkable substance ever discovered,” and other observers were no less thrilled. A 2015 ExtremeTech piece posited the idea that graphene “could change the course of human civilization.”

So far, graphene has already shown extraordinary promise in the semiconductor industry. (That New Yorker piece also mentioned specific uses, as on ice-resistant helicopter blades, scaffolding for those suffering spinal-cord injuries and inflatable rafts and slides used in airplanes.)

Magnetizing graphene takes things to the next level, but it is not easy to do. Before 2019, that could only be accomplished by adding magnetic coatings or compounds. But Swiss and German researchers teamed up last year to solve this riddle, constructing a nanostructure made of graphene and then manipulating the spin of the electrons in such a way that they produce a magnetic field.

This new field — spin transport electronics, or spintronics — is defined as the manipulation of electrons’ spin to achieve a certain end. For example, it can be altered to provide for data storage or transfer.

Spintronics are superior to conventional electronics in that they don’t rely on electric current to sustain their spin and are reliable in environments with high temperatures or high radiation. The spin of an electron is identified as discernable magnetic energy even though atoms are capable of spinning up/clockwise and down/anti-clockwise. In theory, spintronics would operate as a hybrid by using both the electron’s spin and charge.

There is an ever-increasing need for data storage, as the amount of data available around the world, estimated to be 33 zettabytes in 2018, is expected to increase to 175 zettabytes by 2025. Much of that will be stored in the cloud, but there will also be a need for smaller and smaller transistors. Those made from silicon have steadily shrunk, from 14 nanometers to 10 and most recently to five, but there is a limit to how small they can get. Magnetized graphene offers the possibility of them getting even smaller. That has obvious implications for hard drives, smartphones and other devices.

In addition, devices using spintronics are more energy-efficient, which would at least in theory reduce the footprint of the world’s data centers. At present they consume about three percent of the global energy supply, and by 2030 could soak up as much as 10 percent.

It is also expected that spintronics will impact robotics. Specifically, it will allow for the production of nanorobots, which, when introduced into a human body, will enable healthcare professionals to more precisely diagnose a patient’s condition.

Finally, there are those who believe that spintronics can hasten the development of quantum computers, which, while capable of solving complex problems, need very precise conditions in which to operate — i.e., low temperatures, a vacuum, etc. Researchers have discovered that manipulating electrons’ spin can allow for such computations, though this technology has yet to be perfected.

It is clear that magnetic graphene holds great potential in any number of areas — that it might yet live up to its hype by impacting not only the technology sector but others as well. There are miles to go before a final determination can be made, of course, but the advances to date have shown promise, and there is no doubt more to come.

An Energizing Combination: Graphene and Perovskite-Silicon Solar Cells

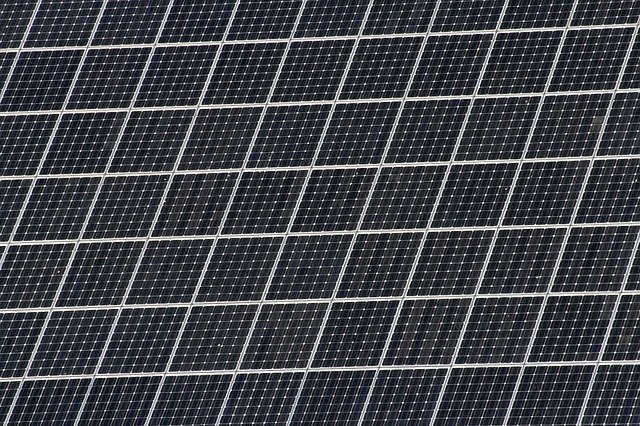

As the world’s dependence on sustainable energy grows, so too does the need for efficient, cost-effective solar cells.

About 1.8 percent of the electricity generated in the U.S. in 2019 was from solar power, and that is only expected to increase. In fact, solar is projected to grow faster than any other energy source between now and 2050. Hence the emphasis on efficiency, and in recent months, researchers at the Italian Institute of Technology (IIT) combined two powerful materials — graphene and perovskite-silicon — to improve it by up to 20 percent.

Until now, standard solar cells — composed of pure silicon or a perovskite-silicon combination — had a maximum efficiency of 32 percent. Cost was also an issue, as even the best of the lot had high fees for operation and maintenance, leading scientists to seek viable alternatives.

Enter graphene, which was only discovered in 2004 when researchers peeled tape off a chunk of graphite and examined the atom-thick layer left behind. Since then, graphene has forever changed the production of electric circuits, medical devices and anti-corrosive paint.

Strong and lightweight, graphene is both more flexible and cost-effective than traditional solutions. Perovskite, meanwhile, is a calcium titanium oxide that, when exposed to sunlight, absorbs photons and generates electrical current.

To develop hybrid solar cells, researchers deposited thin-film graphene flakes to the perovskite-based solar cells, which immediately boosted the photovoltaic performance of the cells without altering their absorption of the sun’s rays.

The result? Higher chemical stability and significant cost reduction.

The recent inclusion of graphene has reduced the reflectance of solar rays by 20 percent, leading to the equivalent increase in efficiency.

It is important to note that while pure silicon is adequate for converting sunlight into electricity, it is a poor conductor. That’s why it’s often paired with perovskite to capture sunlight more readily.

In standard perovskite-silicon solar cells, the perovskite top cell is stacked over a silicon base and then pressurized. Used in tandem, the cells reach a power conversion efficiency of 26.3 percent over a small area.

Though the combination achieves relatively high efficiency at a lower cost, perovskite-silicon is considered relatively unstable and difficult to scale.

Though it’s an emergent technology, hybrid graphene and perovskite-silicon cells are poised to completely disrupt the solar energy market. Experts state that it’s just a matter of time before the use of hybrid solar technology enables the commercialization of cost-effective, large-area solar panels.

Researchers noted improvement in virtually all facets of solar cell tech with the inclusion of graphene, improving charge collection, energy generation, and energy transport.

Best of all, the new combination is set to reduce the manufacturing costs of solar cells. The new solar cell serves as the foundation of the European Commission-funded Graphene Flagship Project (GRAPES), which seeks to surpass the infamous 30 percent solar conversion mark while keeping production costs minimized.

After three years of intensive research, the world’s first graphene-based solar farm is being set up in alignment with UN goals for sustainable development in 2020. Keep your eye out for more reliable, effective, and cost-minimized solar panels as they hit the market.